The Proma THC SD

$400.00

-

This is a torch height controller electronics for plasma cutters.

Connect the plasma Voltage to the controller and set the control Voltage and the controller will produce the torch up/down and on signals to control the machine s Z-axis keeping a constant torch height making a high quality cutting, saving you tips and not at last can cut bent, not straight sheet materials too.

3 in stock

Description

The Proma THC SD is a new generation of plasma torch height controller. It is based on the popular Compact THC 150 model.

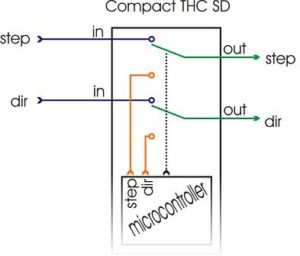

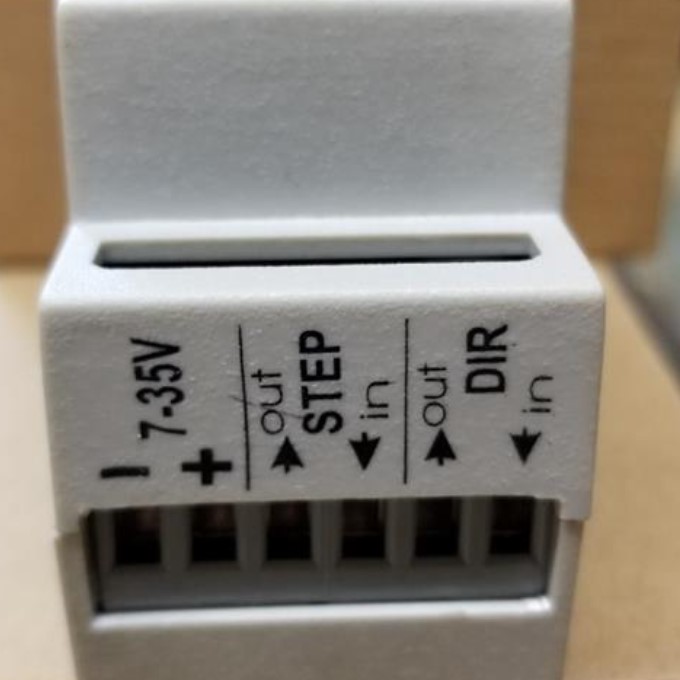

The Proma THC SD inputs / outputs generate corrective signals of step/dir proportionally to the slope of the material.

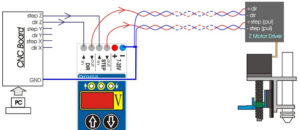

The connection method of a controller “beyond the software” allows you to use it with the

software without the THC function.

Intended for use with any control system that uses STEP/DIR signals to control the Z axis.

Simplified Block diagram:

Pilot Arc Voltage Neutralizer – protection system, which is responsible for

removing spikes in the AC electrical flow, which can be caused by a plasma

source with contact-less arc striking (HV/HF pilot arc) generating a high voltage

or from surges coming from plasma cutters equipped with contact arc striking

system.

Main Arc Voltage Divider – While in operation, the cutter generates dangerous

voltage levels, unsafe for precision electronics. A voltage divider system is

incorporated to reduce this voltage to a safe level.

A quick acting filter system removes any interference that may pass through a

voltage divider.

Filtered and scaled voltage values derived from the plasma cutter’s “raw arc

voltage” are then sent to the brain of the device. The “brain” consists of a

programmed microprocessor, which in addition to the analysis of the cutting

voltage parameters and proper output blocks controlling, also supports the LED

display and function keys.

A built-in switching power supply ensures compatibility in a wide range of power

supply voltages without the need for heat sinking. The power supply connection

is optically isolated from the rest of the system which allows you to use to share

power from existing systems providing they output the recommended voltage.

The last block is an output system, which transmits signals to the stepper motor

controller.

Reviews

There are no reviews yet.